How to Choose the Right Wire or Cable

How to Select the Ideal Wire or Cable for Your Application

Choosing the right wire or cable for your specific needs is crucial to ensure optimal performance and safety. Various factors must be evaluated to make an informed decision. Learn more in this comprehensive guide to help you select the ideal wire or cable for your application.

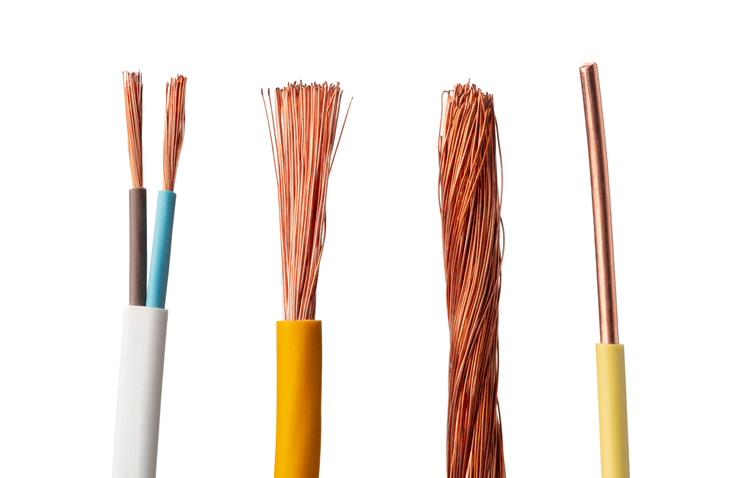

Understanding Conductors

The first aspect to consider is the type of conductor material. Common options include:

- Bare Copper: Known for its excellent conductivity and flexibility, one of the most used conductor metals.

- Tinned Copper: Offers enhanced corrosion resistance, ideal for high-moisture environments, one of the most used conductor metals.

- Aluminum: This metal has similar properties to copper; ductility, malleability and conductivity. Conductor costs are reduced with aluminum, providing cost savings specifically in larger gauge sizes.

- Bronze Coated Steel: Offers high tensile strength, this material is the best choice for coaxial cables or special cords.

- High Strength Alloys: High strength alloys offer high breaking strength and greater flex life with only a small increase in DC resistance.

Choosing the right conductor depends on the specific requirements of your application, including conductivity, flexibility, and environmental factors.

Importance of Insulation

The insulation material of a wire is critical for ensuring safety and durability. Key considerations include:

- Temperature Resistance: Determine the maximum temperature the wire will encounter. For high-temperature environments, materials like PTFE or silicone are ideal.

- Exposure to Elements: Consider whether the wire will be exposed to moisture, chemicals, or oils. Materials like PVC or rubber provide excellent resistance to these elements.

Selecting the appropriate insulation ensures the longevity and reliability of the wire in various conditions. Learn more about insulation types in IEWC’s Popular Insulation Types technical guide.

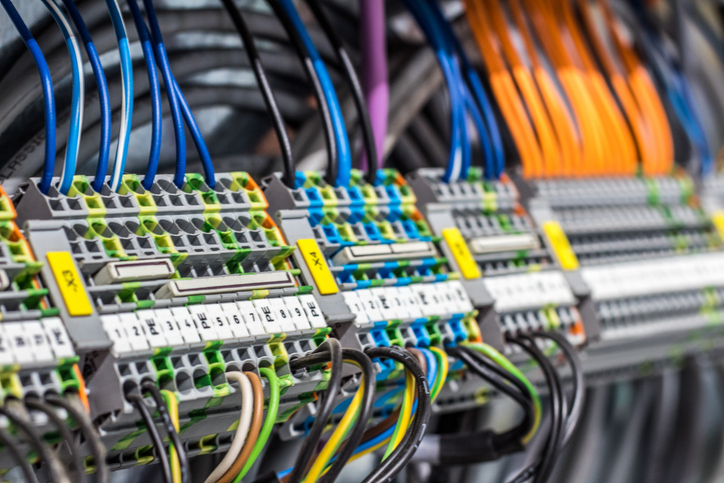

Protective Coverings

In many applications, additional protective coverings, a jacket or sheath, are necessary to safeguard the wire from physical damage. Common options include:

- Thermoplastic: A material which will soften, flow, or distort when subjected to sufficient heat and pressure.

- Thermosetting: A material which will not soften, flow, or distort when subjected to heat and pressure.

The choice of jacket depends on the environmental hazards and mechanical stresses the wire will face, learn more about the popular jacket types here.

Value-Add Product Services for Wire and Cable

Need an additional service added to a basic wire or cable? With capabilities that can help advance your company, IEWC strives to be your most entrusted business partner. Our product value-add services are aimed to help accelerate and simplify your business, saving you time and money. Some services include:

- Kitting: Maximize your production efficiency, reduce your procurement overhead, and consolidate transactional costs

- Etching: A chemical process that allows your wire and cable to be exposed to harsh conditions and chemicals.

- Striping: Need to differentiate between conductors? IEWC can add colored stripes to your wire to make identification pain-free.

- Printing: Allow us to add your designated mark to your product, helping customize your process and save time with accurate labeling

- And More!

Ensuring that the wire or cable meets your unique needs can save time and money. Learn more about how IEWC can assist with our Value-Add Product Services.

Example Scenario

Consider the case of PVC-coated wires. The hardness of PVC can differ between manufacturers, potentially affecting how easily the wire can be processed. Different equipment may produce varying results, but machine adjustments can usually be made to accommodate these differences. This example highlights the importance of understanding material properties and their impact on processibility.

Selecting the right wire or cable involves evaluating multiple factors, including conductor material, insulation, and protective coverings. By considering these aspects, you can ensure that your chosen wire or cable will perform reliably and safely in its intended application. Always consult with a wire and cable expert to make the most informed decision for your specific needs, Contact IEWC to speak to one of our product experts.

Related Resources

What is a Wire?

Wire refers to a single, usually cylindrical, strand or rod of metal which is used to carry electricity and telecommunications signals. Learn More

What is a Cable?

Cable, or cabling, consists of the twisting together of two or more insulated conductors.Learn More

Selecting a Conductor

Even in the design of a simple single insulated wire many factors must be considered, including physical properties of the conductorLearn More