Hook Up Wire and Lead Wire

Whether working with motors, power circuits, or small appliances, you are likely dealing with hookup wire and lead wire varieties.

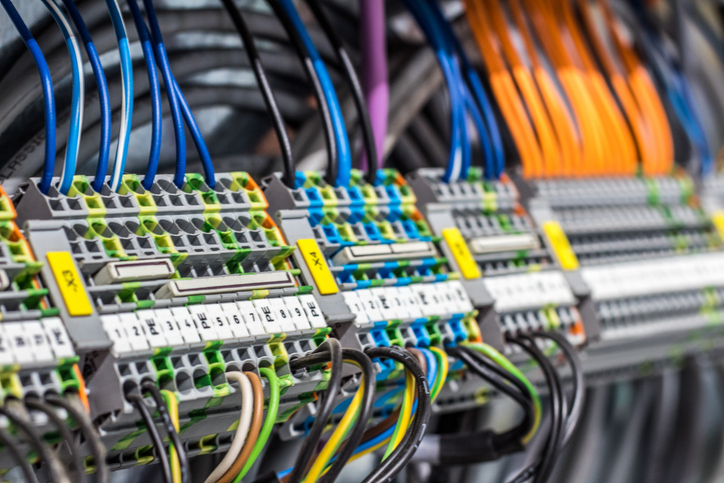

Hookup wire and lead wire are typically single conductor wires insulated with plastic or rubber. These are the wires you most commonly see in electronic equipment—in switchboards, panels, and circuitry in a variety of household and even industrial applications.

What is Hookup Wire?

What is Hookup Wire?

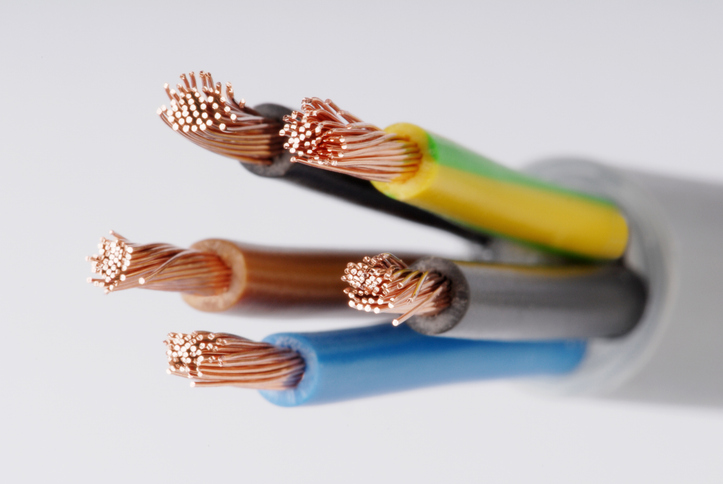

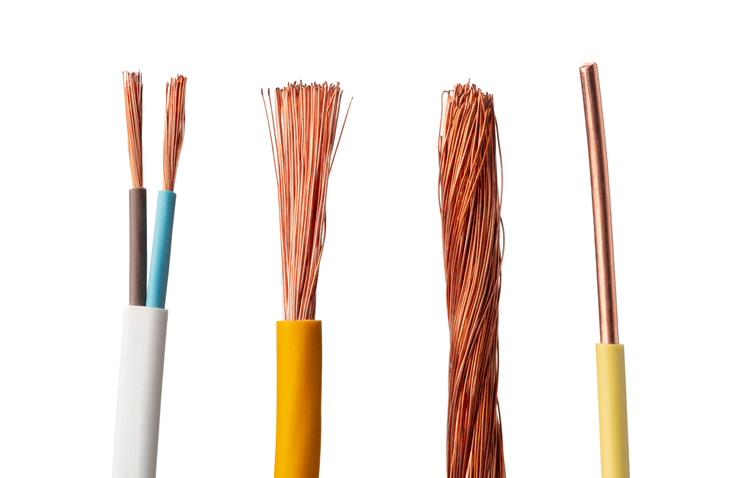

So what is hookup wire? Hookup wire is a type of lead wire. Hookup wires are a type of insulated wire with a copper conductor. The copper may be stranded or solid, bare copper or tinned copper. When manufacturers use "tinned copper” in hookup wire, it means the wire features a tin coating. The coating helps make the wire easier to solder and connect. While the tinning process slightly impacts the conductive properties of the hookup wire, it's typically insignificant to the wire's performance.

Hookup wire is one of the most readily recognizable types of wire out there and is appropriate for most general use. There is also automotive hook-up wire and different products suited to various industries. You'll find these thin, insulated wires throughout common electrical equipment (hence the term "appliance wire," after the place where these types of wires are frequently seen).

As discussed in this guide, hookup wire products fall into different certifications. UL and CSA certifications are used for hookup wire to indicate size and capacity. UL stands for Underwriters Laboratories, an international safety science testing laboratory in the United States. The independent group tests products and technology for safety, setting the standards for 22 billion products each year.

CSA previously stood for Canadian Standards Association but is now a Nationally Recognized Testing Laboratory (NRTL) for all of North America. Similar to the UL, CSA is an independent regulatory organization that performs testing on electronic products. Both organizations test for safety, capacity, and performance.

Most wire, including hookup wire, contains a CSA or UL certification rating based on voltage or temperature tolerance. We also carry wire with international ratings (such as European-specific approvals), as well as non-UL materials like welding cable, battery cable, and specifically marked non-UL cordage. Automotive wire is subject to the Society of Automotive Engineers or SAE ratings as well. These numbers can guide you through your choices and help you select the most appropriate wire for your application.

Differences Between Hookup Wires and Lead Wires

What’s the difference between hookup wires and lead wires? Technically, this is a trick question because hookup wires ARE lead wires. A lead wire is simply a wire that connects to different electronic components.

Lead wires usually contain strands of copper wire conductors with plastic, rubber, silicone, or other insulation. In many lead wires, the copper conductor wire is stranded and tinned.

Hookup wire is a lead wire used in many different low-current (and low-voltage) electronic applications. So, when you hear the term hookup wire, you know someone is referring to a type of lead wire.

Uses for Hookup Wires

As previously mentioned, hookup wires are ubiquitous in household electronics and control panels. Hookup wires are used in many small household appliances—from blenders to ovens to vacuum cleaners. Many tools and small machines require hookup wire, and they're found in electrical appliances and low-current applications.

On an industrial scale, automotive hookup wires are used throughout the automotive industry and in many different motors. Many industrial machines use hookup wires in control panels, motorized components, generators, and power sourcing.

You will also find hookup wire in computer equipment. Switchboards and control panels use hookup wire. Hookup wire is found in printers and many other electronic devices. The medical industry uses hookup wire in their electronics, as does the military. In the most critical applications, special-rated wiring is used for these sensitive hookup wires.

How to Select Hookup Wire

When trying to select hookup wire for your application, several factors can guide you through your selection. If you aren't sure which choice is appropriate for your needs, contact us. Our IEWC representatives will be more than happy to walk you through the best hookup wire for your situation.

In the interim, here are some of the most important factors to consider when selecting hookup wire.

Standard Ratings

Your application may require your hookup wire to meet UL or CSA standards, depending on the situation. The wire listing will include the corresponding standard, making it easy to search.

NEC Compliance

State and local regulators often require compliance with NEC (National Electric Code) standards for certain electronic installations. The NEC is another layer of safety standards to examine when selecting wire.

Temperature Rating

Hookup wire has a temperature rating, indicating the maximum temperature threshold for safe use. Most PVC insulated wire is rated at 105 C, but the performance can also depend on certain environmental factors. ETFE and PTFE wires are designed for higher-temperature applications.

Voltage Rating

Hookup wires are rated for different voltages, as well. The voltage capacity often depends on the insulation type, and it can differ between the different hookup wire selections.

Wire Materials and Coating

Hookup wires are mainly made from stranded, tinned copper conductor material, allowing for easy soldering and providing corrosion resistance. However, there are other materials available such as solid copper and aluminum.

The insulation and jacket material of the wire will also vary between wire options. Most commonly, hookup wires are insulated with PVC insulation, silicone insulation, or Teflon (PTFE and ETFE varieties). XPLE or cross-link polyethylene (XPLE) is another highly common type.

While all hookup wires and insulation materials are designed for electronic use, some offer more protection in certain environments. Insulation thickness impacts voltage rating too. For example, UL 1007 and 1015 are PVC insulated wires. 1007 is thinner, rated at 300V while 1015 is thicker and rated at 600V.

Find Hookup Wires at IEWC

In general, hookup wires and lead wires are some of the most common wires used in many electrical appliances and low-current applications. Although wiring can seem like a minor factor in a larger project, it plays a vital role. Choosing safe, well-made hookup wires that can perform reliably is essential.

At IEWC, we're an industry leader in wiring and cable. We carry a vast inventory of lead wire, hookup wire, connections, and other products to ensure your wiring works safely and effectively. If you need assistance choosing the best lead wire for your application, please contact us or request a quote. Our team will be happy to help you find the right product.Related Resources

What is a Wire?

Wire refers to a single, usually cylindrical, strand or rod of metal which is used to carry electricity and telecommunications signals. Learn More

UL 1015 Hook-Up Wire Guide

Explore the ins and outs of UL 1015 hook-up wire, gaining a deeper understanding of its uses and advantages. Read More

GPT Wire

GPT wire is one of the most common types of wire in the automotive industry. If you’re looking at the wire inside a vehicle, chances are you’re looking at GPT wire. Read More