Motor Lead Ratings

Understanding UL1446 Motor Insulation Standards and IEEE Test Guidelines

With electric motor performance and safety, the choice of insulation materials and wire temperature ratings is critical. The UL1446 motor insulation standards and IEEE test guidelines outline specific requirements to help ensure the longevity and safe operation of motors. These standards categorize insulation systems into different classes, each with a corresponding minimum wire temperature rating.

Classes of Motor Insulation Systems

The UL1446 standards specifies four primary insulation classes for electric motors: B, F, H, and R. Each class represents a different level of thermal endurance and is associated with a specific temperature range:

- Class B: Insulation systems classified under Class B must withstand a minimum temperature of 130°C. The wire used in these systems should have a minimum temperature rating of 90°C.

- Class F: For Class F insulation systems, the minimum thermal endurance requirement is 155°C. The wire used must be rated at least 125°C.

- Class H: Insulation systems in Class H need to tolerate temperatures up to 180°C, with a minimum wire temperature rating of 150°C.

- Class R: Class R insulation systems are designed for extreme conditions, requiring a minimum insulation temperature of 220°C. The wire used in these systems must have a minimum rating of 200°C.

The UL1446 motor standards and IEEE test guidelines state:

| Class | Insulation System | Min. Wire Temp. |

|---|---|---|

| B | 130C | 90C |

| F | 155C | 125C |

| H | 180C | 150C |

| R | 220C | 200C |

Importance of Correct Wire Temperature Ratings

For motors to operate safely and efficiently, it is vital to use wires that meet or exceed the minimum temperature ratings specified for each insulation class. If the wire is not rated within 5°C of the rated insulation temperature, additional measures must be taken to ensure protection. When the wire temperature rating does not meet the required insulation class, a protective barrier such as sleeving must be applied to the "hot spots" within the motor. This sleeving serves to increase temperature protection and maintain the motor’s safe operation. By adhering to these guidelines, manufacturers can prevent overheating, reduce the risk of insulation failure, and extend the lifespan of the motor. The minimum wire temperature rating is not arbitrarily set; it is determined by both UL (Underwriters Laboratories) and the Original Equipment Manufacturer (OEM). These ratings are based on rigorous testing and assessment to ensure they meet safety standards under specific operational conditions.

Adhering to Standards for Optimal Motor Performance

Compliance with UL1446 motor insulation standards and IEEE test guidelines is crucial for achieving optimal motor performance and safety. By using properly rated wires and applying protective measures where necessary, you can help ensure that your motors operate efficiently and reliably in their intended environments. This attention to detail not only protects the motor, but also safeguards the broader system in which it operates.

Related Resources

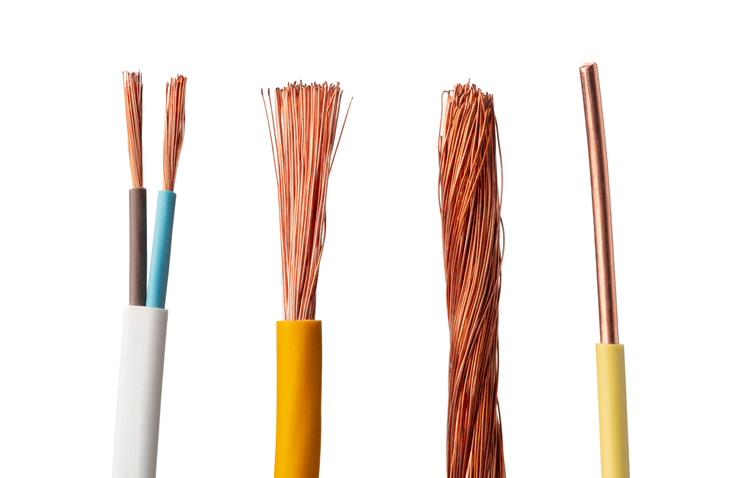

What is a Wire?

Wire refers to a single, usually cylindrical, strand or rod of metal which is used to carry electricity and telecommunications signals. Learn More

What is a Cable?

Cable, or cabling, consists of the twisting together of two or more insulated conductors.Learn More

Application & Selection Guide for Standard Product

Read more on the typical applications for standard wire and cable products.Read More