Transformer Wiring: Choosing the Right Cable for Voltage Management

Electrical distribution is dependent on transformers. They allow for an increase or decrease to help ensure that power moves safely and effectively through grids, industrial systems, and other operations.

The best transformers are only as effective as the cables that connect them and transport the power. A high-quality transformer can underperform and even fail if it’s paired with the wrong wire.

So here’s what you should consider when selecting transformer wiring. Today, we'll examine the key factors to consider when choosing the ideal cable for your specific application.

Why Transformers Need Voltage-Specific Cable

Transformers manage voltage; it’s their primary purpose and function. A step-up transformer increases the voltage, allowing electricity to move efficiently over long distances. The counterpart, a step-down transformer, reduces the power to safe levels, allowing it to be used in facilities, buildings, and for equipment.

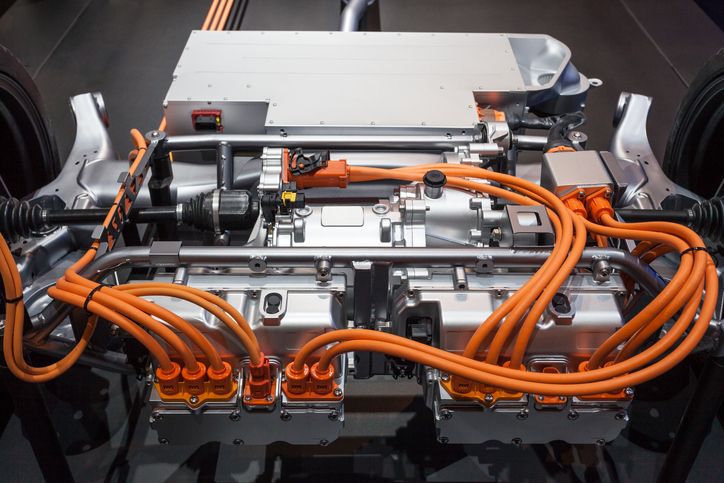

A transformer has two sides—the primary side, where the voltage enters, and the secondary side, where the voltage exits. Cable selection must be correct to handle and transport the electrical load throughout the process.

Cable selection is often an afterthought, but it’s one of the most critical factors in ensuring safe and efficient voltage management. Choosing the correct cable means long-term durability and helps you avoid energy loss. It also prevents overheating and keeps your installation code compliant.

The wrong choice of cable, on the other hand, can lead to many issues. The incorrect selection can create safety hazards and lead to costly downtime. It can also result in code violations. When an installation doesn’t meet code, you can face expensive project delays and even rework.

Mismatching your cable to your application is potentially dangerous. Undersized and improperly insulated wire can overheat when subjected to an electric load. Overheating can damage surrounding components and insulation, or worse, ignite a fire.

The wrong-sized cable also creates excessive resistance, which dissipates energy as heat. This inefficiency counteracts the effectiveness that the transformers are designed to deliver.

Transformer wiring does more than make a connection. The cable and wire selection for your transformer is a factor in the power transfer efficiency, heat dissipation, and system reliability. In commercial buildings and manufacturing applications, transformers must guarantee that the energy is consistently safe and usable.

Key Factors in Transformer Cable Selection

When sourcing wire and cable for transformers, several key factors must be explored and established. It’s not just a matter of simply matching the wire size to the current. You also need to consider the voltage, conductor material, insulation type, and the environment in which the cable will be used.

The voltage rating is the starting point for selecting your cable. Each cable or wire you choose must be rated to safely carry the primary and secondary voltages of the transformer. Low-voltage transformers (600 volts or lower) are often used in residential and most small commercial settings.

Larger applications, such as industrial plants, utility systems, and campuses, may require a medium-voltage transformer (operating between 5 and 35 kV). While most day-to-day building infrastructures don’t call for high-voltage installations, they are found in specialized circumstances and applications. Regardless of the need, it's essential to select a cable rated at or above the operating voltage to ensure safe operation.

Conductor type also requires careful attention. The industry standard has long been copper because of its superior strength, durability, and conductivity. Copper cables are typically small in diameter and easy to install in tight spaces.

The drawback of copper is that it can be expensive and heavy, especially in large-scale installations where weight and cost are concerns. Aluminum is an affordable and lighter alternative, but requires a larger diameter for the same performance and careful termination to avoid connection issues.

Insulation is another crucial component in selecting your transformer wiring. THHN and other thermoplastic insulations are the go-to choice for low-voltage commercial applications. These solutions are easy to work with and cost-effective.

For medium- and high-voltage systems, thermoset insulations such as cross-linked polyethylene (XLPE) or ethylene propylene rubber (EPR) offer improved heat resistance and durability. These materials can also withstand moisture and chemicals, so make certain to consider the environment in which the application will be used.

Temperature rating is vital for the safe operation of transformer cables and wires. A cable should withstand the ambient temperature of the installation site and the heat generated by the electrical load. In certain scenarios, such as confined conduits, bundled installations, and high-load situations, heat buildup can be significant.

Awareness of the temperature rating helps ensure that the insulation performs as expected and avoids premature degradation. Getting properly temperature-rated wire and cable enables you to prevent system failures.

Shielding is also a necessity for transformer applications, particularly at medium and high voltages. Shielding helps prevent electrical stress, EMI (electromagnetic interference), and enhances the system's safety. Shielding protects both the cable and surrounding sensitive equipment.

Application environmental condition is another important consideration. A transformer used outdoors in a substation will face much more rigorous demands than one installed in a clean indoor facility. Moisture, underground burial, direct sunlight, chemical exposure, and even rodent activity can all factor into the insulation and jacket material considerations. When you pair a cable with the right environment, you get reliable, long-term performance.

All transformer cable and wiring choices are guided by compliance. This means that the materials must adhere to NEC requirements in the United States, as well as UL listings, IEEE and ICEA standards, and local authority (AHJ) rulings. Compliance helps ensure the project's safety and also helps you avoid violations and non-compliance concerns during inspections.

Typical Cable Types for Transformer Applications

Different transformers require different classes of cable. For low-voltage systems up to 600 volts, cables like THHN, XHHW-2, and USE-2 are the standard selections. These transformer wires and cables are used throughout commercial buildings, institutional facilities, and residential developments. They're cost-effective and flexible enough to be the appropriate choice for these environments.

Medium-voltage systems, up to 35 kilovolts, require more robust cables, such as MV-90 and MV-105. These cables are designed for higher voltage resistance, and typically have robust thermoset insulation and shielding. They are the optimal solution for industrial plants, campuses, and utility-scale applications—whenever transformer loads are heavier, and distances are longer.

Transformers typically need power cables, as well as control and signal wiring. Control and signal wiring are made of smaller-gauge cables that support functions like temperature monitoring and remote operation. Even though these smaller cables don't carry heavy loads, they're essential for safe transformer operation.

Common Cable and Wire Selection Mistakes to Avoid

Despite the ubiquity of detailed codes, standards, and guidelines, mistakes in cable selection and installation are quite common. One of the most frequently made mistakes is underestimating the voltage requirements, which can cause significant safety risks.

Another mistake is failing to account for temperature derating when cables are bundled and installed in conduits. In these close quarters, overheating can be a significant issue.

Some installers overlook the importance of flexibility and minimum bending radius requirements, which can pose a hazard in tight spaces. It’s also crucial to consult local codes and industry standards to ensure that your installation is up to code. Even a well-planned installation must pass inspection.

Properly sizing cables to match the transformer's current and load capacity helps maintain efficient performance and prolong the life of the equipment. Fortunately, all of these selection mistakes can be avoided with the proper supplier support.

Transformer wiring isn’t an “anything goes” decision. Often, off-the-shelf cable will suffice, but it's essential to consider all the factors of the application and tailor the solution to the specific situation. If you need guidance, it's critical that your supplier offers more than just available inventory.

A reliable cable supplier will offer technical expertise to help you make the proper cable and wire selection. Cable suppliers should stand behind their products, offering the necessary compliance documentation. Because transformer installation is often on a tight project timeline, it’s also important to choose a supplier that can deliver inventory quickly.

At IEWC, we offer a comprehensive selection of transformer-rated cables. Choose from low-voltage and medium-voltage solutions. Our technical team is here to support you through each step of the specification process, helping you ensure your cables are code-compliant and optimized for long-term performance.

Need help selecting transformer wiring and cable? Reach out to IEWC today, and we can guide you towards the best choice for your application.

Related Resources

What is a Cable?

Cable, or cabling, consists of the twisting together of two or more insulated conductors.Learn More

High Voltage Wire & Cable Guide

High-voltage or HV wire and cable are necessary for many industrial applications that rely on dependable high-power transmission. Whether you’re looking for the right HV cable for your application or trying to learn more about how HV wire and cable work, we’ll break it down for you.Learn More

How to Choose the Right Wire or Cable

In selecting a wire or cable for an application, several factors should be considered. Learn More