Choosing Turbine Control, Motor, & Instrumentation Cables

Turbine control systems and other demanding industrial environments require reliability at all times. Your control, motor, and instrumentation cables must do their job in the most challenging conditions, including extreme heat, mechanical abrasion, persistent moisture, and ongoing exposure to oil and chemicals.

At IEWC, we offer high-performance power distribution cable made to ensure precision, power continuity, and above all, system safety. Our inventory includes process control cable options such as SJOOW and THHN cables. Here’s how to select the right cable for even the most intense job.

Turbine System Demands

Turbine systems generate energy. Whether we’re talking about gas turbine power plants or wind turbines, the system consists of a rotating shaft that drives energy into a generator for power. The energy may come from burning natural gas, kinetic energy from wind, steam, and hydroelectric turbines.

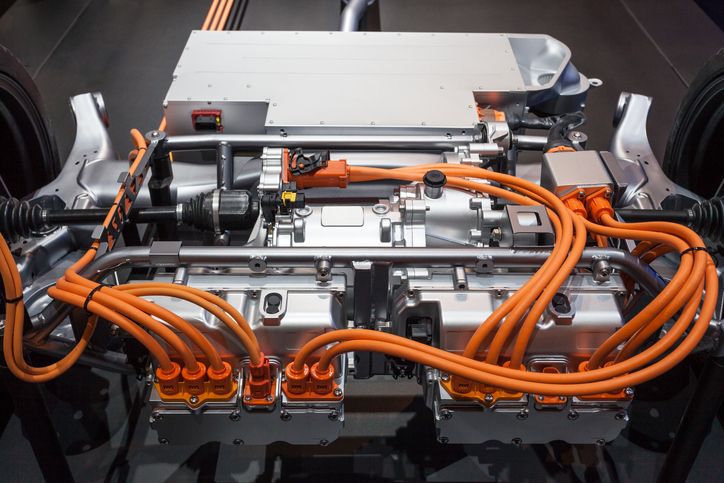

Cables are used throughout turbine applications to power motors and auxiliary systems, to transmit signals that monitor speed and emissions, and to connect to sensors that monitor safety concerns and offer real-time diagnostics.

To perform under pressure, these cables must be flexible but firm. The quality of the cable can impact the efficiency, reliability, and safety of turbine system operations. Even a minor signal or power delivery disruption can result in costly downtime, safety hazards, and equipment damage.

Communication between sensors and controllers is crucial for delivering stable power to rotating machinery. This communication is also vital for system diagnostic accuracy to keep the power stable and uninterrupted. The correct cable for each function is essential to your operational safety and success.

SJOOW cables and THHN cables are the two main types of cable used in turbine systems. Below are the similarities and the differences between these two control, motor, and instrumentation cables.

SJOOW Cables: Flexibility Meets Durability

SJOOW cables tell us a lot just by the name. S stands for service cord, a general-purpose, flexible cable. J stands for junior, indicating it's rated for 300 volts instead of 600 volts SOOW cables. The OO indicates an oil-resistant jacket and oil-resistant insulation. The W in SJOOW tells us that it’s weather and water resistant.

These factors built into SJOOW cables make them among the most versatile cord options for industrial applications. SJOOW cables are particularly well-suited for mobile equipment in the dynamic power generation environment.

The jackets and insulation of SJOOW cables are always made of thermoset rubber material (along with the insulation). The rubber offers flexibility but remains durable in harsh environments.

Typically, jackets are made from CPE (chlorinated polyethylene) or EPDM (ethylene propylene diene monomer) rubber. These materials resist oil, ozone, water, and UV exposure. They remain flexible even in cold temperatures and withstand mechanical stress like dragging, bending, and coiling.

The insulation is typically also made of EPDM rubber. The rubber offers excellent dielectric strength to protect against voltage. It provides thermal stability and heat resistance while maintaining flexibility.

Thermoset rubbers like EPDM and CPE don't melt when heated. These types of rubber are very good at maintaining shape and properties, even under environmental stress. These qualities make them an excellent choice for industrial applications.

The oil-resistance of the jacket and insulation makes these cables suited for the greasy, oily turbine enclosures. Water and weather resistance are other key factors, as many turbine applications are in outdoor environments.

The Junior rating for 300 volts indicates that SJOOW cable isn't the right choice for high-voltage applications. However, the rating is ideal for control circuits, portable motor control applications, and interconnects.

SJOOW Applications Include:

- Temporary turbine test stations

- Portable turbine lighting systems

- Instrumentation panels

- Mobile generator equipment

SJOOW cables are commonly the go-to for entertainment, marine, and mining industries. Because of their rugged construction and superior flexibility, they are a preferred solution for turbine facility applications requiring temporary installation and repeated movement.

SJOOW cable is lightweight, flexible, and easy to work with in tight spaces and for portable configurations. When selecting the best cable for an application, ensuring the voltage rating of the SJOOW cable is appropriate for the job is essential.

THHN Cables: High-Performance for Fixed Installations

THHN cable is another primary type of cable used in turbine control. THHN stands for thermoplastic, high-heat-resistant, nylon-coated cable, making it the backbone of many fixed electrical systems in industrial environments. THHN cables are particularly appropriate for applications where cables need to run through a conduit while also withstanding chemical exposure and high heat.

Why select THHN cables for your application? The cables are rated up to 600 volts, taking them out of the Junior category and making them suitable for motor control, power distribution, and branch circuit wiring.

The insulation or primary layer of THHN cable is typically PVC (polyvinyl chloride), as indicated by the "T" for thermoplastic insulation. This offers electrical insulation, flame-resistance, and temperature resistance up to 90°C in dry locations.

The H represents heat resistance up to 75°C and high heat resistance up to 90°C in dry environments. This level of heat resistance offers safety and stability in turbine rooms, where heat generation is a significant concern. THWN or THWN-2 cable is the choice for wet environments.

The “N” in THHN cable tells us that the jacket is made of nylon, which offers abrasion, UV, chemical, and oil resistance. The nylon jacket provides a low-friction surface, making it easier to pull through the conduit and adding mechanical strength to the cable.

UL lists THHN cable for conduit and raceway use, a prevalent choice for conduit systems. Typical THHN applications in turbines include:

- Powering turbine pumps and motors

- Connecting sensors to instrumentation panels

- Switchgear control and motor control wiring

- Permanent conduit wiring in utility rooms and mechanical enclosures

THHN cables are made of solid and stranded copper conductors. Stranded is the better choice for easy routing and flexibility, while solid is cost-effective with some improved conductivity over short distances.

The related cable THWN-2 may be a more solid choice for installations exposed to moisture. However, THHN cable is still the preferred and most reliable selection in many turbine applications.

Application-Specific Cable Selection

If you’re selecting cables for a turbine system, look beyond voltage. Here are additional factors to consider in your selection criteria.

Will the cable be fixed in a conduit, or will it need to offer movement and flexibility? Will the cable be exposed to water, oil, chemical risk, or UV light? Will the cable carry motor power or signal control? What are the temperature ranges of the application? Finally, does the cable meet UL, NEC, and OSHA safety standards?

In many cases, SJOOW is commonly used for mobile turbine tools, and THHN is the choice for motor control and power distribution.

It’s essential to choose the best cable for the job! The wrong cable selection can result in premature wear, system inefficiencies, and costly maintenance and downtime. Always err on the side of safety, performance, and compliance.

Standards & Compliance You Can Trust

Most cables perform essential jobs, but industrial cables for turbine systems must meet stringent regulatory requirements. At IEWC, we're well-versed in helping you with the right cables to comply with major national and international standards, including UL, NEC, CSA, and CE approvals.

Our standards and certifications go beyond regulatory compliance. They're also safety measures to help you trust that the cables were made for reliable performance, even in high-demand applications. This is especially crucial in operations where the most minor component failures can lead to massive loss.

With decades of experience in wire and cable distribution, we’re your partner for power and precision. Our inventory includes thousands of cable types—all thoroughly vetted for performance.

Our technical experts will help you find the right cable to match your specs. With fast turn-around, delivery, and reliable stocking programs, we'll ensure you always have what you need on hand—whether you're building a new power generation facility or updating your existing systems.

Every turbine system has unique electrical and mechanical demands. Let the experts at IEWC help you specify and source the best instrumentation cable for your operation. Reach out today and connect with a technical representative or request a quote.

Related Resources

What is a Cable?

Cable, or cabling, consists of the twisting together of two or more insulated conductors.Learn More

High Voltage Wire & Cable Guide

High-voltage or HV wire and cable are necessary for many industrial applications that rely on dependable high-power transmission. Whether you’re looking for the right HV cable for your application or trying to learn more about how HV wire and cable work, we’ll break it down for you.Learn More

How to Choose the Right Wire or Cable

In selecting a wire or cable for an application, several factors should be considered. Learn More