CSA vs. UL Style Comparison Guide

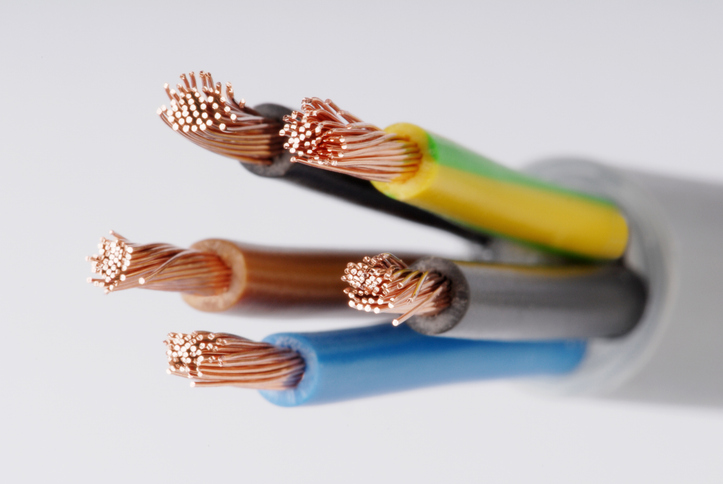

In the world of electrical applications, choosing the right wire is essential for a seamless and efficient connection. Two primary contenders in the market are Hook-Up Wires and UL Styles. While both serve similar purposes, understanding their key differences can make all the difference in your project's success.

In the world of electrical applications, choosing the right wire is essential for a seamless and efficient connection. Two primary contenders in the market are Hook-Up Wires and UL Styles. While both serve similar purposes, understanding their key differences can make all the difference in your project's success.

What are the CSA vs. UL Wire Standards?

UL Standards represent the culmination of UL's vast safety research and scientific knowledge. With a rich history spanning over a century and the creation of over 1,500 Standards, UL holds recognition as an accredited standards developer in both the US and Canada. Embracing a global commitment to public safety, UL Standards collaborates with national standards bodies in various countries, working together to construct a safer and more sustainable world.

The CSA standards in Canada pertain to safety regulations for a wide range of products, including electrical appliances, medical devices, machinery, and equipment. The importance of CSA standards lies in their role in ensuring the safety of relevant electrical products. Compliance with CSA standards is obligatory for all applicable electrical products to guarantee their safety and conformity with regulations.

Specific UL Wire Standards

Here are a few specific UL wire standards:

- UL 758 (Appliance Wiring Material - AWM): Specifies requirements for conductors (single-conductors and multi-conductors) and fiber-optic materials used in appliances. It covers aspects such as insulation, temperature ratings, and voltage ratings.

- UL 1581: Reference standard for electrical wires and cables, and flexible cords, detailing conductor requirements, insulation, jackets, and coverings. It also includes methods for sample preparation and testing to mitigate installation and operational failures.

- UL 1061, UL 1569, and UL 1015: These standards specify different insulation thicknesses and temperature ratings for hook-up wires. UL 1061 has the thinnest insulation, rated to 300V and 80°C, UL 1569 has medium insulation thickness, rated to 300V and 105°C, and UL 1015 has the thickest insulation, rated to 600V and 105°C.

- Flame Test Standards (UL 1666, UL 1685): These standards evaluate a wire's flame resistance and behavior in fire conditions. They are critical for applications where fire safety is paramount, such as in building installations and industrial environments.

Specific CSA Wire Standards

The following are some specific wire standards from the CSA:

- CSA C22.2 No. 127: Specifies requirements for appliance wiring material, ensuring safety and performance in various applications, including household appliances and industrial equipment.

- CSA C22.2 No. 210: Covers specific requirements for power and control cables, including aspects such as insulation, conductor materials, and testing methods to ensure reliability and safety in electrical installations.

Considering Different UL Styles

When it comes to differentiating UL Styles of wires and selecting the most suitable one for your specific application needs, several key factors must be considered. Depending on the requirements of your project, including temperature and voltage ratings, environmental conditions, and industry standards, use our table below to help you choose the right one.

UL Wiring Applications

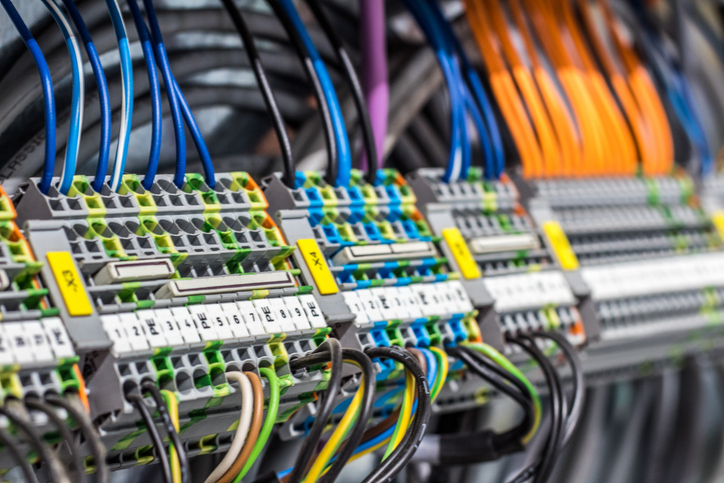

UL wire finds extensive applications across various industries due to its high safety and quality standards. One primary application is in the electrical and electronics industry, where UL wire is commonly used for internal wiring in appliances, power tools, electronic devices, and more. Its flexibility, durability, and resistance to environmental factors make it an excellent choice for these applications.

UL wire is prevalent in automotive manufacturing, where it serves as a reliable solution for vehicle wiring systems, ensuring stable and efficient electrical connections. Moreover, the aerospace industry utilizes UL wire for critical applications, such as avionics, where safety and performance are paramount. Other applications include medical equipment, industrial machinery, and renewable energy systems, like wind and solar, where UL wire guarantees consistent and safe power distribution. The versatility and adherence to stringent safety standards make UL wire a trusted choice for a wide array of applications in diverse sectors.

UL Styles & UL Wire Types Guide

There are a variety of hook-up and lead wires that meet UL and CSA standards, which ensure that a product is safe for use. It can be confusing to differentiate them and find one that meets your application needs.

The table below details various features, characteristics and uses of UL and CSA style wires to help you navigate the large collection of hook-up and lead wires. IEWC stocks an intensive offering of hook-up and lead wire that meets UL and CSA standards. Reach out to us if you need help deciding which meets your needs!

There are a variety of hook-up and lead wires that meet UL and CSA standards, which ensure that a product is safe for use. It can be confusing to differentiate them and find one that meets your application needs. The table below details various features, characteristics and uses of UL and CSA style wires to help you navigate the large collection of hook-up and lead wires.

IEWC stocks an extensive offering of hook-up and lead wire that meets UL and CSA standards. Reach out to us if you need help deciding which meets your needs!

|

TPT |

Tinsel Parallel Thermoplastic |

|

TS |

Tinsel Service |

|

TST |

Tinsel Service Thermoplastic |

|

SPT – 1 |

Service Parallel Thermoplastic – 1/64” Insulation |

|

STP – 2 |

Service Parallel Thermoplastic - 2/64” Insulation |

|

SPT – 3 |

Service Parallel Thermoplastic - 3/64” Insulation |

|

SPE – 1 |

Service Parallel Elastomer – 1/64” Insulation |

|

SPE – 2 |

Service Parallel Elastomer – 2/64” Insulation |

|

SPE – 3 |

Service Parallel Elastomer – 3/64” Insulation |

|

SV |

Service Vacuum |

|

SVO |

Service Vacuum Elastomer |

|

SVOO |

SVO with Oil-Resistant Insulation & Jacket |

|

SVT |

Service Vacuum Thermoplastic |

|

SVTO |

SVT with Oil-Resistant Jacket |

|

SVTOO |

SVTO with Oil-Resistant Insulation & Jacket |

|

SVE |

Service Vacuum Elastomer |

|

SVEO |

SVE with Oil-Resistant Jacket |

|

SVEOO |

SVEO with Oil-Resistant Insulation & Jacket |

|

SJ |

Service Junior |

|

SJO |

SJ with Oil-Resistant Jacket |

|

SJOO |

SJO with Oil-Resistant Insulation & Jacket |

|

SJOOW |

SJO with Oil-Resistant Insulation & Jacket, Indoor/Outdoor use |

|

SJT |

Service Junior Thermoplastic |

|

SJTO |

SJT wit Oil-Resistant Jacket |

|

SJTOO |

SJTO with Oil-Resistant Insulation & Jacket |

|

SJE |

Service Junior Elastomer |

|

SJEO |

SJE with Oil-Resistant Jacket |

|

SJEOO |

SJEO with Oil-Resistant Insulation & Jacket |

|

S |

Service |

|

SO |

Service with Oil-Resistant Jacket |

|

SOO |

SO with Oil-Resistant Insulation & Jacket |

|

SOOW |

SO with Oil-Resistant Insulation & Jacket, Indoor/Outdoor use |

|

ST |

Service Thermoplastic |

|

STO |

ST with Oil-Resistant Jacket |

|

STOO |

STO with Oil-Resistant Insulation & Jacket |

|

STOOW |

STO with Oil-Resistant Insulation & jacket, Indoor/Outdoor use |

|

SE |

Service Elastomer |

|

SEO |

SE with Oil-Resistant Jacket |

|

SEOO |

SEO with Oil-Resistant Insulation & Jacket |

|

HPN |

Heater Parallel Neoprene |

|

HSJ |

Heater Service Junior |

|

HSJO |

HSJ with Oil-Resistant Jacket |

|

HS |

Heater Service |

|

HSO |

HS with Oil-Resistant Jacket |

If you need more information from IEWC or would like to request details on the price or availability of a product, please reach out. We’re here to help you find the right solution to your application.

Related Resources

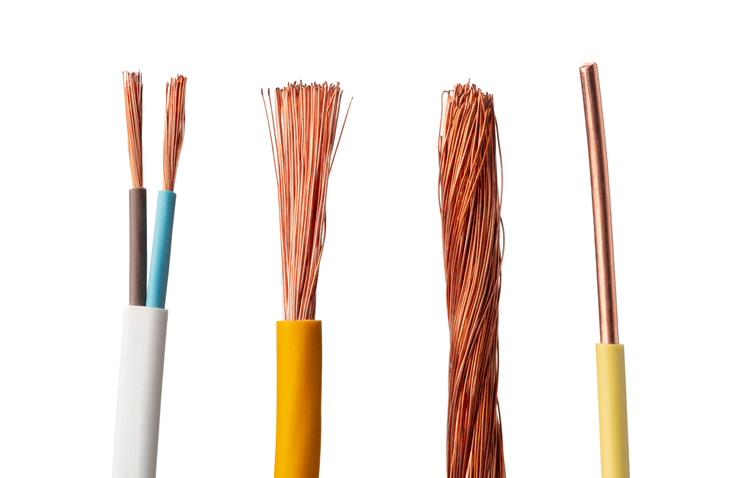

What is a Wire?

Wire refers to a single, usually cylindrical, strand or rod of metal which is used to carry electricity and telecommunications signals. Learn More

How to Choose the Right Wire or Cable

In selecting a wire or cable for an application, several factors should be considered. Learn More

Hook Up Wire and Lead Wire

Hook up wire and lead wire are typically single conductor wires insulated with plastic or rubber. These are the wires you most commonly see in electronic equipment—in switchboards, panels, and circuitry in a variety of household and even industrial applications.Learn More