Motor and Servo Cable Basics for Modern Motion Systems

Motor and servo cables are crucial components in industrial automation. Motor cables supply power, while servo cables also carry low-voltage feedback signals; together, they help motion systems perform as expected.

Understanding the features of motor and servo cables, including the impact of continuous flex and torsional motion, helps ensure you choose the best cable for your application. The right cable helps prevent downtime, surprise maintenance needs, and other hassles that can slow down stable system operation.

What Motor and Servo Cables Do

The first step in getting to know motor and servo cables is to dig into their construction. This helps you connect your cable selection to your application requirements and to ensure you have the right flex and torsional capabilities to support dynamic industrial environments. Although they’re discussed together, they’re not quite the same.

- Motor cables deliver power between the drive and motor.

- Servo cables include power conductors and low-voltage signal pairs for transmitting feedback to the drive.

Servo systems depend on clean, accurate communication. Disruptions such as EMI, conductor fatigue, and mechanical wear can cause positioning errors, damaging vibrations, overheating, and even system-wide shutdowns. So servo feedback cables often require enhanced shielding and insulation to prevent noise and drift.

When looking for cable, be sure to choose a motor or servo cable that maintains electrical stability under demanding environmental and mechanical conditions. Both types of cable can experience continuous flexing, torsion, vibration, and similar environmental stress, but the internal makeup is designed for their different roles.

If you’re depending on precision, speed, and consistent uptime, your cable selection is crucial. Servo and motor cables are used in a wide variety of industrial applications and environments, many of which are dynamic and require strong communication support.

Typical applications for servo and motor cables include:

- Industrial robots and articulated arms.

- Packaging, pick-and-place.

- Labeling machines,

- Automated storage and retrieval systems.

- Conveyors and material handling.

- CNC machining centers.

- Assembly automation and gantry systems.

Even in tough environments, motor and servo cables must withstand repeated motion and heavy use. It's important to select the top cable for your situation. A good cable choice can make a world of difference.

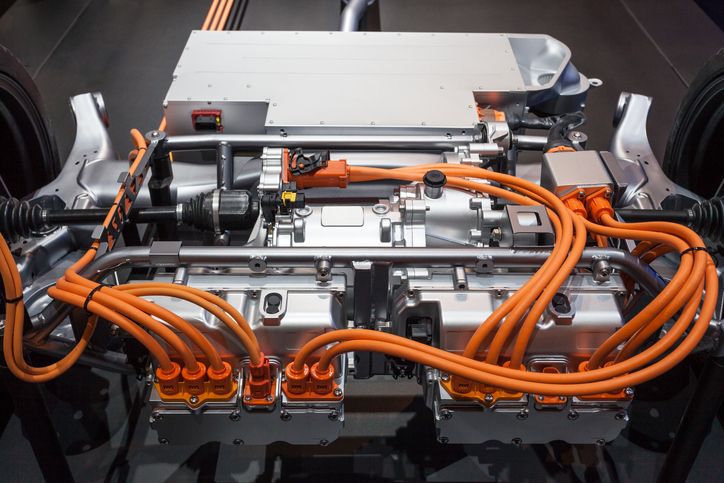

Key Components of Motor and Servo Cable Construction

What are the critical components that make up motor and servo cables? Cable designs vary by manufacturer and application, but most share several critical construction elements that allow them to perform continuously and reliably.

Conductors

In motor and servo cables, fine-stranded annealed copper conductors are the standard choice. These conductors offer:

- Flexibility and high performance even in repetitive motion applications

- Less bending fatigue

- Lower resistance (compared to coarser stranding)

Tinned copper conductors are another common choice for applications that require corrosion resistance or easy termination.

The conductor size is selected to match the motor power requirements, voltage drop limitations, thermal considerations, and the specifics of the system.

Insulation

The insulation for motor and servo cables needs to stand up to electrical stress, vibration, temperature fluctuations, and other environmental challenges. When it comes to insulation, there are several good selections. Your choice will depend on the cable's situation and the application requirements:

- PVC (Polyvinyl Chloride): An excellent general-purpose insulation.

- PE (Polyethylene): A low dielectric constant insulation offering improved signal performance.

- PP (Polypropylene): Has excellent electrical properties and stability.

- TPE (Thermoplastic Elastomer): Is highly flexible and temperature resistant.

In the case of servo feedback cables, insulation choice is an especially crucial factor to consider. Low-voltage signals are more susceptible to interference and leakage, so insulation must be stable.

Shielding

Shielding protects signal and power conductors from experiencing electromagnetic interference (EMI), crosstalk, and electrical noise.

For servo cables, especially feedback pairs, and many motor cables, the typical shielding options are:

- Foil shields for 100% coverage

- Braided copper for mechanical durability.

- Combination shields (foil + braid) for high EMI protection.

Some feedback cables need multiple shields. They may require individual shields around twisted pairs, along with an overall braid that wraps around the entire cable. In high-noise environments, the extra shielding helps maintain data accuracy.

Cable Jacket

A motor or servo cable’s outer jacket provides another layer of protection from abrasion, oil, chemicals, impact, and flex stress. It's best to select cable with a jacket material designed to withstand your specific mechanical and environmental conditions.

Common jacket material options for motor or servo cables include:

- PVC: an affordable, versatile jacket option.

- PUR (Polyurethane): offers strong abrasion resistance with flexibility.

- TPE: the ideal choice for low-temperature or high-motion applications.

In applications that require continuous flex and torsion, jacket flexibility and resistance to tearing are particularly crucial.

Understanding Flexing and Torsion in Dynamic Motion Applications

Motor and servo cables often undergo a high amount of mechanical stress, including bending, twisting, and multi-axis motion. By matching the cable construction to your application, you'll avoid issues like conductor breakage, insulation cracking, and electrical faults — any of which can lead to premature failure and costly downtime.

Movement, or, in this case, flexing and torsion capabilities, are major considerations in your cable selection, especially for dynamic systems and applications that move.

Continuous Flex Cables

Continuous flex cables are often the best choice for applications where the cable repeatedly moves along a single plane (as in a cable carrier, sliding assembly, or linear actuator). Consider the fact that a cable might bend millions of times over its service life, and standard cables aren't engineered to hold up under that level of repeated motion stress.

Continuous Flex Cables Feature:

- Fine conductor stranding to help reduce internal stress.

- A short lay length to distribute bending forces more evenly.

- Flexible insulation materials to help prevent cracking.

- Movement-friendly fillers to maintain shape and reduce internal friction.

- Abrasion-resistant jackets to protect against environmental damage and wear.

When selecting a cable for a moving application, look for one that’s rated for continuous flex. The flexibility of your cable will lengthen its lifespan and make it more reliable in automated motion systems.

Torsional Motion Rated Cables

Torsion-rated cables are specially engineered to withstand twisting along their longitudinal axis. Twisting can often happen in rotating assemblies, multi-axis automation equipment, and robotics. In these applications, a cable may experience ±90°, ±180°, or greater rotation per meter of cable length, so properly rated cable is essential.

Unlike conventional bending, torsional stress can damage all layers of the cable—the conductors, fillers, shields, and jackets. Choosing the wrong cable can mean a lot of issues down the road, including shield breakage, conductor strain, jacket tearing, and signal degradation.

Torsion-Rated Cables Feature:

- Specialized conductor stranding for controlled displacement.

- Reinforced shielding designed to resist tearing, even during flexing and rotation.

- Optimized lay lengths to help balance twist forces along the cable.

- Flexible jacket materials that resist cracking and wear.

- Multi-layer construction to help stabilize internal components even under twisting stress.

Torsional ratings are determined through testing that ensures durability throughout thousands, or even millions, of twisting cycles. The performance of the torsion-rated cable is typically specified in degrees per meter.

Environmental and Mechanical Factors That Affect Cable Performance

There are several factors to consider when choosing the right motor and servo cable for your application. The electrical and mechanical conditions must be assessed, along with all factors that will affect the environment where the cable is housed.

Considerations include:

- Temperature: especially for cables installed near motors and heated machinery.

- Chemical Exposure: lubricants, oils, coolants, process chemicals, and solvents can degrade cable jackets and insulation.

- Speed: faster cycles result in higher mechanical loads; cables should be rated for the equipment's speed.

- Bending Radius: cables have a minimum bend radius; choosing a cable below the rated radius results in too much stress and fatigue.

- EMI: industrial systems often operate in high-noise environments, so cables need shielding.

- Mechanical Support: measures such as strain reliefs, cable carriers, and proper routing can help prevent stress and extend cable life.

If you’re choosing a motor or servo cable, it’s important to carefully examine how it will be used and match the cable construction to your application.

For stationary and light-duty applications, PVC or PUR jackets are typically the right choice along with standard conductor stranding. Basic shielding may also be used, as long as EMI levels are low.

For applications that require dynamic flexing, look for cable with a continuous-flex-rated conductor and shield design. PUR jackets are typically the best choice, as they offer high abrasion resistance. Also, look for optimized lay lengths that are designed to improve and support bending performance.

Rotational and robotic applications call for torsion-rated cables. Look for cables with reinforced braid shields and multi-layer jackets that inhibit tearing. The materials in the cable must be able to handle multi-axis (multi-directional) movement.

Choosing the appropriate cable for your application is extremely important. The mechanical design of the cable must match the operational environment to offer the longest service life and lower your risk of downtime, maintenance, or failure.

Motor and servo cables feature advanced flexing and torsion capabilities. These are typically the best cable selections for:

- Six-axis robotic arms

- Automated welding cells

- Pick-and-place equipment

- Delta robots

- Packaging machinery

- CNC machines and machining centers

- Applications with continuous motion cycles

- Automated guided vehicles (AGVs)

- Conveyor systems

- Gantry robots

- Industrial printing and converting equipment.

There are many other potential applications for motor and servo cables as well. When an application requires motion support, the appropriate cable helps ensure accuracy, system efficiency, and cycle reliability.

It’s important that you can rely on your motor and servo cables to provide stable power and clean signal transmission. Often, they are connecting expensive components and valuable systems under some of the most demanding conditions. It’s crucial to match the cable to the application.

If you need assistance selecting cables engineered for continuous flex or torsional motion, we’re here to help. At IEWC, we offer a wide selection of reliable, top-quality cables. Our support team is here to help you find the perfect fit. Reach out today or request a quote.

Related Resources

What is a Cable?

Cable, or cabling, consists of the twisting together of two or more insulated conductors.Learn More

High Voltage Wire & Cable Guide

High-voltage or HV wire and cable are necessary for many industrial applications that rely on dependable high-power transmission. Whether you’re looking for the right HV cable for your application or trying to learn more about how HV wire and cable work, we’ll break it down for you.Learn More

How to Choose the Right Wire or Cable

In selecting a wire or cable for an application, several factors should be considered. Learn More