Wire Ampacity Chart & Guide

Are you looking for the best wire size for your application? A wire ampacity chart is a critical tool that can help you make the determination. Ampacity charts show the appropriate size wire for a given application that will safely conduct currents without posing a risk of overheating or a fire hazard.

Of course, if you have any questions or concerns as you explore these wire ampacity guidelines, please reach out. Our team at IEWC can help you determine the ideal products for your specific situation. When it comes to selecting wire ampacity, it’s no guessing game!

What is Wire Ampacity?

What is wire ampacity anyway? The word ampacity is a mashup of ampere capacity. In other words, it refers to the maximum capacity of a cable or conductor; how much it can carry before it sustains deterioration.

You may also see ampacity referred to as current carrying capacity. Any time you’re working with wire or cable, it’s an important factor to know. It helps you to make sure that you’re always playing it safe with wire and cable. Proper ampacity can also improve the operating efficiency.

Overlooking or ignoring a wire's ampacity can lead to fire risk, insulation damage, and eventual electrical failure. This is why a licensed electrician or engineer uses ampacity tables based on standard testing methods and conditions before they choose wire sizes and types. It’s also crucial to create safe electrical systems to meet regulatory requirements, building codes, and safety standards.

What Factors Determine Wire Ampacity?

While ampacity is a relatively simple calculation, it can also be influenced by several factors. If you’re determining the ampacity of a wire, you’ll need to consider:

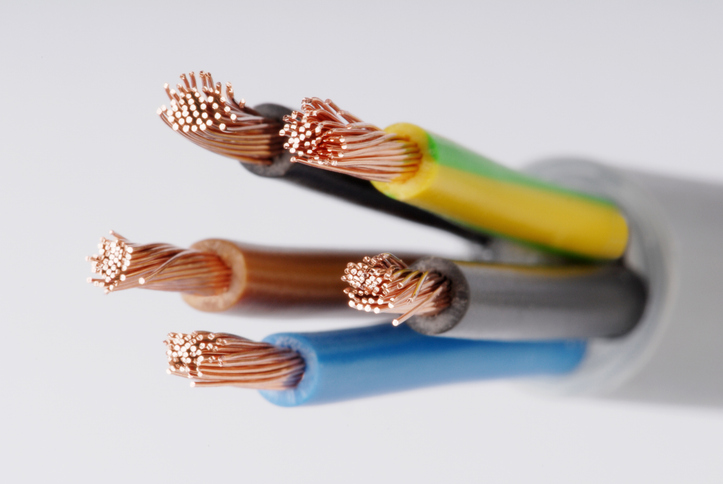

- Conductor/Wire Size: The larger the wire gauge size (or circular mil area), the higher the capacity. Larger AWG wire sizes have more surface area to dissipate heat and offer a bigger cross-sectional area for the flow of currents.

- Conductor Materials: A wire's material impacts its ability to carry current. Copper and aluminum are the industry's go-to conductor types. Copper has a higher ampacity than aluminum.

- Number of Conductors: Heat dissipation abilities are reduced as more individually insulated conductors are bundled together.

- Insulation Type: Insulation materials protect wire conductors as they conduct electrical energy. Different insulation types can tolerate different heat levels, impacting a wire's ampacity. The insulation must be temperature-rated for the maximum heat generation of an application.

- Installation Conditions: Environmental conditions also play a big role in a wire's ampacity. Ambient temperature and installation method (conduit, duct, direct burial) will impact ampacity because cables in hotter environments have lower ampacity. Most charts feature temperature correction factors. You can mitigate hot conditions with forced air cooling and ventilation.

Calculating Load Requirements

How do you calculate the amperage load requirements of a circuit?

- Calculate the number of appliances on the circuit, power rating, and power consumption.

- Calculate the amperes: Current (A)=Power(W)/Voltage(V).

- Include a safety margin and align calculations with the circuit breaker capacity.

Sounds complex? Let’s simplify each of these steps with a little more insight into the process.

1. List Appliances and Their Power Ratings

Start your calculation by creating a list of all the devices connected to the circuit. Each electrical appliance will feature a power rating (often in watts) on the appliance itself or within the user manual. This rating tells you how much power the item uses to operate.

2. Add Up the Total Power Consumption

Once you have the list, add the power ratings of all devices on the circuit. This will give you the total power consumption—basically, how much power you would need to run everything on the circuit at once.

3. Calculate the Current Requirement

To determine the current (in amperes) that the circuit needs to handle, use the formula:

Current (A)=Total Power (W)/Voltage (V)

In most residential cases in the United States, standard circuits have a 120-voltage capacity and 240-voltage for large appliance circuits (like those that power ovens, dryers, and other such items).

The voltage can vary greatly depending on the industry and parameters in industrial applications. The most commonly used transformers in the U.S. are 208V, 240V, 480V, and even up to 600V, but for the most robust situations, high-voltage gear may be required.

4. Include a Safety Margin

It's also important to add a safety margin to the amperage requirement calculations. A circuit will overheat and eventually wear out if forced to run at the maximum capacity for too long. The general rule is to add 20% to your calculation.

5. Check the Circuit Breaker Capacity

The circuit breaker must be able to handle the current (with the additional safety margin). It should have a higher rating than your calculation to avoid constant tripping.

The wires you select for your application must be able to handle the circuit's maximum current. The right wire size and material should be able to handle the load. By making sure the wire ampacity is aligned with the circuit's load requirement, you'll be code-compliant and safe.

Wire Ampacity Charts

|

SUGGESTED AMPACITIES (All Types of Single Conductor Insulation)

| |||||||

|---|---|---|---|---|---|---|---|

|

AWG

|

80°C

|

90°C

|

105°C

|

125°C

|

150°C

|

200°C

|

250°C*

|

|

AMPERES PER CONDUCTOR

| |||||||

|

30

|

2

|

3

|

3

|

3

|

3

|

4

|

4

|

|

28

|

3

|

4

|

4

|

5

|

5

|

6

|

6

|

|

26

|

4

|

5

|

5

|

6

|

6

|

7

|

8

|

|

24

|

6

|

7

|

7

|

8

|

8

|

10

|

11

|

|

22

|

8

|

9

|

10

|

11

|

12

|

13

|

14

|

|

20

|

10

|

12

|

13

|

14

|

15

|

17

|

19

|

|

18

|

15

|

16

|

18

|

20

|

22

|

24

|

29

|

|

16

|

18

|

20

|

24

|

26

|

29

|

32

|

37

|

|

14

|

20

|

25

|

33

|

40

|

40

|

45

|

39

|

|

12

|

25

|

30

|

45

|

50

|

50

|

55

|

54

|

|

10

|

35

|

40

|

58

|

70

|

70

|

75

|

73

|

Correction Factors For Various Air Temperatures

| Temperature (°C) | 80C | 90C | 105C | 125C | 150C | 200C | 250C |

|---|---|---|---|---|---|---|---|

| 30 | 1.00 | 1.00 | 1.00 | 1.00 | 1.00 | 1.00 | 1.00 |

| 40 | .88 | .90 | .92 | .95 | .96 | .97 | .98 |

| 50 | .75 | .80 | .82 | .89 | .91 | .93 | .95 |

| 60 | .58 | .67 | .73 | .83 | .87 | .91 | .95 |

| 70 | .35 | .52 | .61 | .76 | .82 | .87 | .93 |

| 80 | - | .30 | .46 | .69 | .76 | .84 | .90 |

| 90 | - | - | .30 | .61 | .71 | .80 | .87 |

| 100 | - | - | - | .51 | .65 | .77 | .85 |

| 125 | - | - | - | - | .50 | .66 | .72 |

| 150 | - | - | - | - | - | .54 | .65 |

| 200 | - | - | - | - | - | - | .49 |

Suggested Current Carrying Capacity Table (Base Temperature at 40C)

|

AWG | 150C Tinned Copper | 200C Tinned Copper | 250C NPC 2% - 10% | 250C "A" Nickel | 250C NPI | 450C NPC - 27% | 450C "A" Nickel |

|---|---|---|---|---|---|---|---|

| 24 | 6.6 | 7.2 | 8 | 4 | 3.3 | 9 | 4.3 |

| 22 | 9 | 9.6 | 10.8 | 5 | 4.4 | 12 | 5.6 |

| 20 | 13 | 14 | 15 | 7 | 6 | 18 | 8 |

| 18 | 17 | 18 | 20 | 9.4 | 8 | 23 | 11 |

| 16 | 22 | 24 | 26 | 12 | 11 | 30 | 14 |

| 14 | 34 | 36 | 39 | 18 | 16 | 45 | 21 |

| 12 | 43 | 45 | 54 | 25 | 22 | 56 | 26 |

| 10 | 55 | 60 | 73 | 34 | 30 | 75 | 35 |

| 8 | 76 | 83 | 93 | 43 | 39 | 104 | 49 |

| 6 | 96 | 110 | 117 | 55 | 49 | 138 | 65 |

| 4 | 120 | 125 | 148 | 69 | 62 | 162 | 76 |

| 3 | 143 | 152 | 166 | 78 | 69 | 182 | 85 |

| 2 | 160 | 171 | 191 | 90 | 80 | 210 | 99 |

| 1 | 186 | 197 | 215 | 101 | 90 | 236 | 110 |

| 1/0 | 215 | 229 | 244 | 114 | 102 | 268 | 126 |

| 2/0 | 251 | 260 | 273 | 128 | 114 | 300 | 141 |

| 3/0 | 288 | 297 | 308 | 144 | 129 | 338 | 159 |

| 4/0 | 332 | 346 | 361 | 169 | 151 | 397 | 186 |

| 250 | 365 | 385 | 398 | 187 | 167 | - | - |

| 300 | 414 | 436 | 452 | 212 | 190 | - | - |

| 350 | 461 | 486 | 503 | 236 | 211 | - | - |

| 400 | 495 | 522 | 540 | 254 | 226 | - | - |

| 500 | 563 | 593 | 613 | 288 | 257 | - | - |

Wire Temperature Rating

| Ambient Temperature (C) | 200C | 250C | 450C | Ambient Temperature (F) |

|---|---|---|---|---|

| 41-50 | 0.97 | 0.98 | 0.99 | 106-122 |

| 51-60 | 0.94 | 0.95 | 0.99 | 124-140 |

| 61-70 | 0.90 | 0.93 | 0.96 | 142-158 |

| 71-80 | 0.87 | 0.90 | 0.95 | 160-176 |

| 81-90 | 0.83 | 0.87 | 0.93 | 177-194 |

| 91-100 | 0.72 | 0.85 | 0.92 | 195-212 |

| 101-120 | 0.71 | 0.79 | 0.89 | 213-248 |

| 121-140 | 0.61 | 0.71 | 0.86 | 249-284 |

| 141-160 | 0.50 | 0.65 | 0.84 | 285-320 |

| 161-180 | 0.35 | 0.58 | 0.81 | 321-356 |

| 181-200 | - | 0.49 | 0.78 | 357-392 |

| 201-225 | - | 0.35 | 0.74 | 393-437 |

| 226-250 | - | - | 0.69 | 439-482 |

| 251-275 | - | - | 0.65 | 483-527 |

| 176-300 | - | - | 0.60 | 528-572 |

| 301-325 | - | - | 0.55 | 573-617 |

| 326-350 | - | - | 0.49 | 618-662 |

| 351-375 | - | - | 0.42 | 663-707 |

| 376-400 | - | - | 0.34 | 708-752 |

Using the Wire Ampacity Charts

To use the wire ampacity charts, you’ll need to identify your current requirement—the maximum that the circuit must carry during normal operation.

Don’t forget to consider factors like the installation’s environmental conditions (ambient temperature, multiple conduit wires). You’ll also need to look at the wire size and the insulation requirements. Follow the column down to find the target wire gauge that can handle all factors, current requirements, and installation conditions.

Folks find wire ampacity charts useful as a safety measure. It can help you have the peace of mind that the wire you’ve selected will handle the electrical load without shorting out or causing a fire hazard.

Properly sized wires will help your system run more efficiently without voltage drop. This can lower energy costs and reduce wear on equipment and circuitry.

When should you consult ampacity charts?

Wire ampacity charts should be consulted when choosing wiring and electrical circuitry. A wire size chart can be especially useful in:

- Residential applications

- Commercial buildings and large-scale installations

- Industrial applications

- Outdoor installations, where the wire may face elements and be exposed to fluctuating temperatures.

One point of note: Regulatory organizations like the Insulated Cable Engineers Association (ICEA) and standards in the National Electrical Code (NEC) outline current ratings for power cables based on testing and standards that consider environmental and operational conditions.

However, the situation is more complex when it comes to appliance wires. These wires' designs and operational contexts may vary, making it challenging to standardize current ratings. The application and installation conditions may have different thermal properties and usage patterns, which have an impact on the current carrying capacity of the wire. As a result of the ambiguity, there are no "official" current ratings that apply universally to allowable ampacities of appliance wires. It's important to consult manufacturer specifications and other factors to help you determine the needed wire based on the cable ampacity chart.

Find Wire and Cable at IEWC

While wire ampacity charts are an important and helpful tool, you may need further guidance in your selection of wire size. If this is the case, reach out. Our team at IEWC will be happy to discuss your options and needs with you.

At IEWC, we carry a vast array of cable and wire to suit all your needs. Explore our wire and cable options to find everything you need for your next endeavor.

Need further guidance?

Contact our team at IEWC to discuss your options and needs!

Frequently Asked Questions

Ampacity is the maximum current a conductor can carry continuously without exceeding its temperature rating. Proper ampacity selection prevents overheating, ensures safety, and complies with NEC and industry standards.

Ampacity charts list allowable current for each AWG size and conductor material. Copper has higher conductivity, so a copper cable of the same gauge carries more current than aluminum. Always select chart values corresponding to conductor material, insulation type, and installation conditions.

Yes. Conductors with higher-temperature insulation (e.g., THHN/THWN versus TW) can carry more current. However, bundling multiple cables increases heat buildup, which may require derating in accordance with NEC sections (such as 310.15).

Higher ambient temperatures reduce cable ampacity, requiring temperature correction factors. Ampacity charts include correction tables to adjust allowable current based on the installation environment.

The National Electrical Code (NEC), especially articles like 310.15(B), 310.16, and tables, govern conductor ampacity selection. Other standards include IEEE and IEC depending on application locality.

Related Resources

Basic Ampacity Values

Ampacity, or current carrying capacity, is defined as the current a conductor can carry before its temperature rise exceeds a permissible value.Learn More

Application & Selection Guide for Standard Product

Read more on the typical applications for standard wire and cable products.Read More

UL, Metric & SAE Strand Charts

Discover additional information on UL, Metric and SAE Strand ChartsLearn More