Selecting HVAC Control Cable & Wire Management Solutions

Your HVAC system is the core of your building’s comfort and air quality infrastructure. Whether you’re working in an office tower or a data center, climate control is crucial. HVACR systems depend on continuous, precise communication between components like thermostats, sensors, motors, and chiller units.

When the temperature control falters, it impacts the building’s energy efficiency, equipment lifespan, and the comfort of its occupants. Behind the scenes, careful cable design and organized wire management help keep it all synchronized and safe.

Why Cable Quality Matters in HVAC and Chiller Systems

HVACR environments are unforgiving—full of temperature swings, vibrations, moisture, and mechanical stress that can wear down electrical components, including cable and wire.

HVAC systems require cables that stand up to strain and meet the challenges head-on.

Many environmental factors can impact HVAC systems, whether it’s a rooftop air handler or an industrial heating setup. Some of the biggest challenges include:

- Thermal Stress: HVACR equipment must support a wide range of operating temperatures during heating and cooling cycles.

- Vibration and Movement: Mechanical stress is common, especially for cables supporting compressors, pumps, and fans.

- Moisture: Cooling, chilling, and air-handling equipment operate close to dew point, creating corrosion risks.

- EMI: With an array of motors, drives, and sensors, electromagnetic interference can damage signal integrity.

When you select HVAC cable, it’s essential to look for purpose-engineered types that fit your application. The right HVAC cable and wire will help you minimize downtime, reduce voltage drop and electrical noise, and avoid service calls. It also extends the life of expensive HVAC equipment.

At IEWC, we offer a wide selection of HVAC cable and connectivity solutions to support reliable performance even in some of the harshest conditions.

Cable Types for Heating, Cooling, and Air Quality Systems

Cable requirements depend on the type of job, the environment, and many other factors. At IEWC, we carry what you need from low-voltage control cables to power distribution and data feedback cabling.

Control and Power Cable

HVAC Control cable powers up thermostats, variable-frequency drives (VFDs), and motor controls. Tray cables, as well as multi-conductor control cables, are flexible, abrasion-resistant options that support fixed and limited range-of-motion installations.

Control and power cables for HVAC should feature PVC, XLPE, or TPE insulation to accommodate the extreme temperature variance. They should also have shielding to suppress interference from drive systems when installed near motors or VFDs. These cables often require oil-resistant or sunlight-resistant jackets, depending on the location of the installation (rooftop versus plant-floor). As with many types of commercial cable, they should feature applicable UL or CSA approvals for open-air or tray installation.

These cables are used in many different applications of HVAC, including compressor drives, heat-pump control, and condenser motors.

At IEWC, we carry cable from industry-leading manufacturers, including Belden and Alpha Wire. These industry-leading brands offer reliable control and performance, even under a continuous thermal load and challenging conditions.

Sensor and Instrumentation Cable

HVAC is all about climate control, which requires precise monitoring of factors like temperature, humidity, and air pressure. To keep track of these factors, systems often require instrumentation and thermocouple cables. These cables offer accurate data transmission and can support BAS (building automation systems).

Some features of sensor and instrumentation cables include twisted-pair construction to avoid noise. Conductors are often tinned-copper or nickel-plated to resist corrosion and feature foil or braided shielding to guard against EMI. (For best performance, shielding is typically grounded at one end only to prevent ground loops.)

Instrumentation cable is available in color-coded pairs to make termination and maintenance simple and safe. It’s especially crucial for temperature sensors, flow and pressure transmitters, CO₂ sensors, and building automation controllers.

Review IEWC’s inventory to help you source the precise gauge, shielding, and insulation for your instrumentation cable needs.

Hook-Up and Building Wire

Another type of wire associated with HVAC is hook-up wire. This type of wire is used for internal connectivity in control panels and air-handling units. The UL-rated conductors feature a high strand count and offer flexibility and fatigue resistance even during repeated thermal cycling.

Hook-up wire options include:

- MTW, TEW, and AWM styles for control cabinets

- 300 V–600 V ratings

- PVC, PTFE, or XLPE insulation to support temperatures up to 105 °C and beyond

We carry the inventory of panel-building and hook-up wire for efficient assembly and consistent performance in motor starters and safety interlocks.

Data and Communication Cable

Many modern HVAC systems must integrate with IoT-based controls. Reliable connectivity requires data cables that are specially engineered to ensure signal integrity even across long runs and in electrically noisy environments.

These cables are often STP (shielded twisted-pair) or data cable. They feature LSZH (low-smoke, zero-halogen) or plenum-rated jackets for interior use, and many feature low-capacitance designs to improve the transmission distance capacity.

At IEWC, we carry a data-grade cable inventory that can help you support smart building systems and data connections to optimize climate performance.

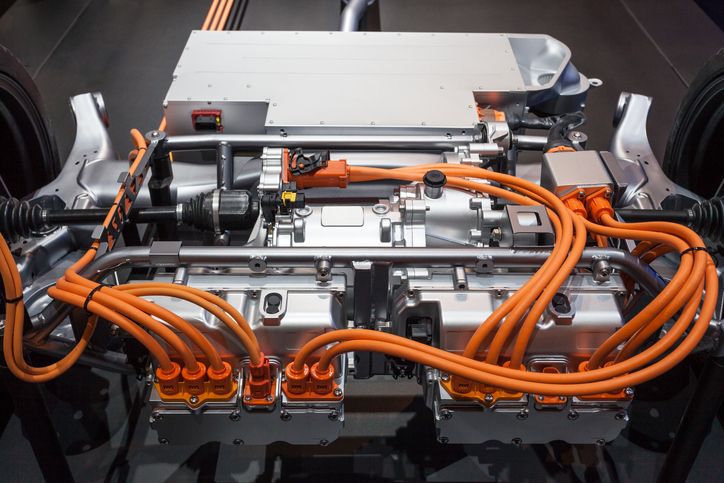

Specialty Cables for Chiller Systems

Chiller systems must allow for exact control over temperature and pressure. The accuracy of sensors depends on stable, low-noise cabling and jackets resistant to hazards such as coolant, oil, and UV exposure.

Depending on the application, specialty cables for chiller systems include:

- Thermocouple wire (Type J, K, T) for precision temperature control.

- PWM- or VFD-rated cable with enhanced shielding and insulation for compressor motors and pumps.

- Low-smoke, zero-halogen (LSZH) cabling options for confined spaces, such as mechanical control rooms.

It’s critical that cables are matched with the correct conductors, shielding, and jacketing options for their environment. The wrong cable can be inefficient at best and at worst, a fire or equipment hazard due to insulation breakdown or overheating.

Cable Management for Organization, Performance, and Safety

Choosing the proper cable is a big part of reliable HVAC installation, but a truly optimized system setup requires organization as well. Cable management includes effective routing, bundling, and strain relief support to ensure a stable and serviceable system.

Essential components of cable management include:

- Cable Ties & Mounts: High-temperature nylon, stainless steel, or UV-resistant polymers that secure bundles in mechanical rooms and rooftop installations.

- Protective Sleeving: Braided or expandable sleeving that is made to shield cables from abrasion and chemical exposure.

- Raceway and Conduit Systems: To help separate power and signal wiring for interference prevention and to simplify future service.

- Labeling and Identification: Printed heat-shrink or adhesive labels make maintenance and compliance clear and straightforward.

At IEWC, we offer cable organization components and kitting services to help you get the needed accessories with your cables. Getting the right components before the installation helps to streamline the process and reduce waste.

Designing for Energy Efficiency and Sustainability

One thing that all parts of HVAC cable infrastructure have in common is that they are made to support safe, energy-efficient operation. Cables must be safe and compliant for each application.

The wrong cable can increase electrical loss and voltage drop. Without a shielded design, you may find false sensor readings that systems can over-correct. Cables must support communication between sensors and BAS controls when necessary, and quality cables should be appropriate and organized to reduce vibrational fatigue (lowering wear and tear on motors and drives).

HVAC and chiller installations must meet a range of safety and performance standards. IEWC’s technical specialists help customers interpret and source cables certified to the correct ratings:

- Temperature Rating: UL 83 (thermoplastic-insulated wire), UL 758 (AWM, for internal wiring)

- Flame and Smoke: UL 1685, plenum-rated

- Environmental Hazards: sunlight- and oil-resistant indications

- Mechanical Protection: Tray cable rating

- Communications: CM, CMR, CMP, or LSZH designation

Cables must feature the right combination of ratings and approvals to comply with inspections and building requirements. Choosing the right cable the first time helps you avoid costly rework and inspection delays.

The bottom line is that every element and component of an HVAC system matters, including the cables and wiring that connect controls and communications.

At IEWC, we have a wide array of options in our portfolio, suited to the needs of control, sensor, and data applications.

Contact IEWC today to explore our full range of HVAC cabling products from control wire solutions. With dedicated technical support and global logistics, our team can help you specify, source, and manage connectivity to keep your climate systems running efficiently.

Related Resources

What is a Cable?

Cable, or cabling, consists of the twisting together of two or more insulated conductors.Learn More

High Voltage Wire & Cable Guide

High-voltage or HV wire and cable are necessary for many industrial applications that rely on dependable high-power transmission. Whether you’re looking for the right HV cable for your application or trying to learn more about how HV wire and cable work, we’ll break it down for you.Learn More

How to Choose the Right Wire or Cable

In selecting a wire or cable for an application, several factors should be considered. Learn More