Selecting Cables and Conductors for Power Distribution

You know that quality equipment is key to reliability in power distribution. But did you know that cable selection is equally crucial? There are several factors that should drive your cable decisions—voltage level, insulation requirements, the environment where your cable will be installed, and the installation method.

This guide provides direction on selecting appropriate cable types, conductors, insulation materials, and performance ratings to match field conditions. Selecting the correct power distribution cable is critical where system dependability is essential.

Key Takeaways:

- Begin cable and conductor selection by assessing the required voltage class and confirming compliance with relevant codes for the application.

- Confirm that the cable’s insulation system and ampacity are sufficient for the installation parameters.

- Evaluate environmental factors such as thermal exposure, moisture, ultraviolet light, chemicals, abrasion risks, and dynamic motion to determine appropriate insulation and conductor sizing.

- The best power distribution cable selection balances electrical performance with mechanical durability and lifecycle cost.

Power Distribution Basics that Affect Cable Selection

Power distribution, control, and instrumentation cables may appear similar at a glance, but they serve very different purposes and are designed to meet different priorities.

Power distribution cables carry high currents over long distances. The insulation and conductor size need to accommodate the voltage, ampacity, and required heat dissipation of the application.

Control and instrumentation cables are designed for lower voltages and lower currents—prioritizing signal integrity, shielding, and noise reduction over raw power capacity.

AC vs DC Considerations

The first factor to look at is AC (Alternating Current) vs. DC (Direct Current). Here’s what to consider with each.

- AC (Alternating Current): AC is standard for most building, industrial, and utility power distribution applications. It’s easier to step the voltage up or down using transformers. AC cable selection is typically driven by the voltage class, insulation system, ampacity, and heat dissipation. Skin effect can become a consideration in larger conductors or higher-frequency AC applications. AC is typically governed by the well-established electrical codes and standards.

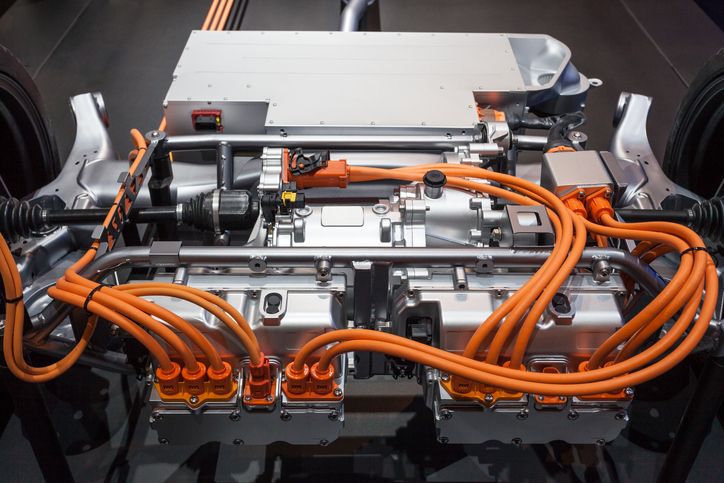

- DC (Direct Current): DC is commonly found in battery systems and renewable energy (such as solar) applications. Data centers commonly rely on DC, as does the transportation sector. The constant voltage of DC creates different insulation stress compared to AC. There’s no zero-crossing, which impacts arcing behavior. DC faults are more difficult to interrupt, so insulation quality and routing are both very important. DC cable selection prioritizes insulation integrity, thermal performance, polarity identification, and grounding practices required for the target application.

Conductor Material

The conductor material of the distribution cable is also very important because it directly affects the cable's current-carrying capacity and installation.

- Copper: Copper is a common conductor choice because it offers a high level of electrical conductivity (a smaller conductor size can carry the same amount of current). Copper is also flexible and can withstand significant mechanical stress. It offers reliable performance in tight spaces with frequent termination, as well as vibration-prone environments. It’s easier to terminate copper, and there are fewer special requirements. Copper can be more costly and heavier than aluminum.

- Aluminum: Aluminum is a lighter and lower-cost conductor than copper. Aluminum conductors must be larger to carry the same current as copper. Aluminum can be more sensitive to oxidation and thermal expansion and requires careful termination practices. Aluminum is commonly found in larger feeders and longer runs. It’s used in utility and industrial distribution applications. Aluminum requires compatible connectors and proper installation to avoid overheating.

Voltage Levels and Insulation Systems for Power Distribution Cables

Power distribution cables are typically broken down into three classes: low voltage, medium voltage, and high voltage, which can directly affect your cable selection.

Low-voltage cable is commonly used in buildings and industrial facilities. Low-voltage applications are typically focused on insulation rating, ampacity, and the installation method.

Medium voltage power distribution cable is often used for campus, plant, and utility distribution. It requires thicker insulation and usually also needs shielding. Specialized termination and testing practices are important to confirm that medium voltage cable is the right option for your application.

High-voltage power distribution cable is typically only used in utility-scale transmission.

The guidelines are usually that higher voltage requires thicker insulation and higher dielectric strength. Medium-voltage systems may require shielding to help control electrical stress and reduce the incidence of partial discharge. As the voltage increases, termination and splicing also become more specialized and critical. Higher voltages also require more stringent handling, storage, and testing to ensure safety requirements are met.

As for insulation systems, several options are available for power distribution cables. Thermoplastic insulation is the easiest to process and is typically rated for lower temperatures. One drawback of thermoplastic is that it can be more susceptible to deformation under higher temperature exposure.

Thermoset insulations offer higher heat resistance with improved long-term thermal aging. These insulations are common in industrial and high-demand environments where temperature is a key consideration.

Other rating factors include wet/dry ratings to determine whether insulation performance is consistent in moisture-prone environments (such as outdoor applications). The ampacity, or maximum current the cable can safely carry, as well as derating factors—the required reductions due to heat, bundling, or installation conditions.

Environmental Considerations that Impact Power Distribution Cable Selection

Environmental conditions are a crucial factor to consider when selecting power distribution cables. Factors like temperature and UV exposure can alter performance, so it’s important to ensure the cable selection is appropriate for the application conditions. Here are the environmental factors to examine.

Temperature

High ambient heat reduces the allowable ampacity of power distribution cables. Elevated temperatures can accelerate insulation aging, shortening the lifespan of the cable. Cold environments, on the other hand, reduce cable flexibility and increase the risk of cracking during installation. It’s important to note that installation temperature limits for your cable selection may differ from its operating limits.

Moisture

A wet conduit behaves very differently from a dry conduit. When a cable is exposed to standing water, the risk of corrosion increases significantly. It’s important to choose wet-rated insulation to prevent moisture-related degradation of the power distribution cable over time. For example, cable used in coastal or humid environments often requires corrosion-resistant materials.

UV Exposure

Prolonged exposure to sunlight can degrade cable jackets, unless they’re UV-rated for the conditions. Outdoor tray cables and rooftop installations are particularly susceptible to UV damage. If your cable will be outdoors in a high-UV-exposure area, choose one with UV resistance to maximize service life and reduce maintenance.

Chemicals

Oils, chemicals, fuels, and solvents can soften and degrade cable jackets, but industrial environments often require their use. It’s important to consider chemical and oil exposure and choose oil-resistant materials. The choice of power distribution cable jacket protects the insulation and the conductor inside the cable.

Abrasion

Cables are tough, but abrasion and mechanical abuse can lead to wear and tear. Pulling and even cable tray usage can also impact abrasion. Armor and thicker jackets help protect your cable against physical damage over time. Consider pulling tension limits and lubricant compatibility of your cable during installation, to get the best option for the job.

Movement

Continuous motion and vibration can stress conductors and insulation. Some cables are more flexible than others and will hold up better in movement-heavy environments. Fine stranding improves cable flexibility. Check that your cable selection has the correct bend radius to prevent premature failure due to motion.

Fire Safety

Flame-rated cables are critical for safety in certain environments. The flame spread, and smoke generation during a fire can greatly jeopardize occupant safety. Examine plenum and riser ratings to ensure control over smoke and toxicity in the event of a fire. Requirements for power distribution cables typically vary by code and installation location.

The Installation Method Matters as Much as Environment

The way the power distribution cable is installed has as much of an impact on its performance and longevity as the environment. Installation methods can affect mechanical protection, heat dissipation, ease of maintenance, and the cable’s susceptibility to physical damage.

Just because a cable performs well in one setting doesn’t mean it will be the same in a similar environment if the routing, support, or enclosure changes. Considering the installation of your cable method helps ensure your cable selection can safely carry its load, while remaining durable and compliant over its lifespan.

- Conduit: Protects the cables from exposure but can trap heat.

- Tray Installation: Improves heat dissipation but increases exposure.

- Open-Air installation: Offers easier cooling but poses a higher mechanical risk.

- Direct Burial: Requires moisture and mechanical protection. Soil chemistry can also affect the outcome.

- Duct Banks vs. Trenches: also impact thermal performance and the accessibility of the cable.

The termination environment of a cable is another critical consideration, as it can impact sealing, strain relief, and your choice of enclosure.

Selecting Conductor Size and Managing Ampacity

How do you select the right conductor size for power distribution cable and plan for the accommodation of ampacity?

Start with the expected load current of the application. Then account for the voltage drop along the cable length.

Ampacity will be influenced by the ambient temperature of the cable environment and the conductor grouping of the cable. Conduit and tray configuration can also impact ampacity. Be cognizant of the insulation temperature rating to ensure your cable can take the heat.

Oversizing cable can reduce heat, lower your losses, and improve long-term reliability. The tradeoff is that oversized cable can have a higher material cost-to-performance ratio, but the price differential is often worth the investment.

Common Cable Families Used In Power Distribution

Selecting the right power distribution cable is easier when you understand the major cable families used for power distribution. These categories reflect how and where cable is installed, the voltage it supports, as well as conditions it needs to withstand.

- Building wire: Building wire is used in conduit systems. It’s most common in commercial and industrial buildings.

- Tray Cable: Tray cable is designed for use in industrial environments. It’s the best choice for exposed cable tray installations.

- Service-entrance/feeder cable: This cable is used to bring power into facilities. It’s rated for specific entry-related conditions.

- Medium-voltage distribution cable: Used for plant or campus power distribution, medium voltage requires specialized handling.

- Portable, extra-hard-use cable: This cable is used for temporary power and for movable equipment. It’s designed for tough conditions, with flexibility and high resistance to abuse.

Selecting Power Distribution Cable

Finding the right power distribution cable for your application requires a careful balance. Consider electrical performance, environmental exposure, and installation realities. In the checklist below, you’ll find a quick reference to ensure all considerations are reviewed during the power distribution cable selection process.

- System voltage and load current

- Indoor or outdoor exposure

- Operating and installation temperature range

- Presence of moisture, oils, or chemicals

- Mechanical stress, movement, or vibration

- Installation method and routing (conduit, tray, direct burial, etc.)

- Required electrical, environmental, and safety ratings

- Termination and splicing requirements

- Product availability and approved equivalents

Cable selection involves evaluating and comparing several factors—electrical, environmental, and mechanical considerations—to ensure you have the ideal cable for your application. By figuring out the right power distribution cable up front, you’ll avoid mismatches and rework that can happen when the cable choices don’t fit the application.

At IEWC, we carry a wide range of cables, including power distribution cables for your projects. We are happy to assist with product selection and planning. Reach out today, and our helpful team will help you find the perfect cable for your application.

Related Resources

What is a Cable?

Cable, or cabling, consists of the twisting together of two or more insulated conductors.Learn More

High Voltage Wire & Cable Guide

High-voltage or HV wire and cable are necessary for many industrial applications that rely on dependable high-power transmission. Whether you’re looking for the right HV cable for your application or trying to learn more about how HV wire and cable work, we’ll break it down for you.Learn More

How to Choose the Right Wire or Cable

In selecting a wire or cable for an application, several factors should be considered. Learn More